8.2.2 Potting

with Plastic

The use of plastics is limited if

- there is friction resulting in wear,

- higher temperatures bring a deterioration in insulation

capacity or

- the mechanical strength falls with rising temperature.

Figure 202: Ceramic component

potted in plastic

Armouring the area at risk with ceramic may

be a solution in these cases. The ceramic insert is placed

inside the injection mould, and is encased and fixed when

the plastic is injected for the component. To achieve the

necessary tolerances of 0.01 mm the insert must usually be

hard machined so that the molten plastic cannot leak out at

the injection stage. The insert will be more effectively anchored

if there are openings in the material and if the insert has

a shape that engages the plastic from behind.

This type of insertion creates a joint with relatively high

mechanical strength, and avoids additional stresses on the

other material. The materials combination of polyamide with

ceramic has been particularly well tried in this context.

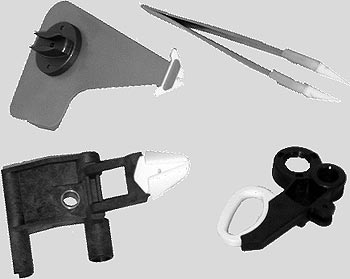

Figure 203: Traversing thread guides

Figure 204: Other ceramic components encased

by injection moulding

|