3.4.1 Silicate

Ceramics

3.4.1.1 Technical Porcelain

Technical porcelains are understood to be

materials in the "alkaline alumina silicate porcelain"

(C 100) group, which find diverse applications in electronics.

As electricity began to be used in the home

and industry, many types of porcelain were already available,

offering excellent properties such as

- high mechanical strength,

- excellent electrical insulation properties and

- outstanding resistance to chemical attack.

As energy consumption rapidly increased

so did the needs of electrical technology, and the properties

of porcelain were continually developed and improved. This

led to today’s alumina porcelain, which

exhibited noticeably greater strength and reliability even

under extreme thermal stress (for example, -50 °C to 550

°C) or sudden temperature changes (during a short circuit

for example), and was clearly superior to quartz porcelain.

Even the long-term behaviour under open air conditions (ageing)

of alumina porcelain is superior to that of quartz porcelain,

and it is therefore used primarily in open air switching stations

and for open-wire insulators (e.g., high tension or train

insulators and supports) by quality-conscious users.

More recent developments indicate that hydrophobic surfaces

improve the electrical properties of the outer layer, and

permit simplified structural forms. The replacement of alumina

with bauxite is a further innovation. This new and significantly

more economical material offers comparable technical properties.

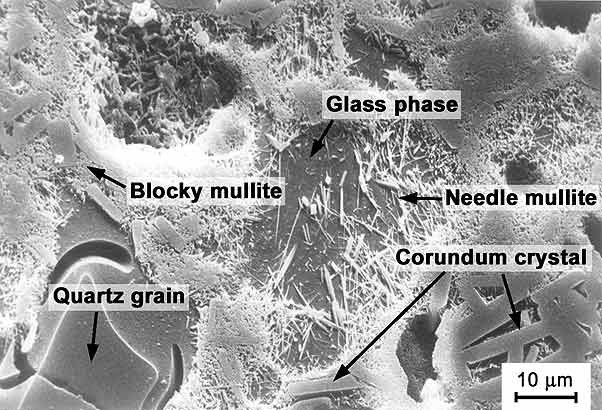

Figure 3: Microstructure

of an alumina porcelain, ground and etched, under a scanning

electron microscope

The difference between quartz porcelain

and alumina porcelain lies in the exchangeable raw material,

i.e. the more economical quartz (SiO2) and the relatively

expensive alumina (Al2O3). For this reason, and because of

the lower production costs, traditional quartz porcelain

represents an economic alternative for moderate load applications.

For a significant number of applications, this is thus a factor

in quartz porcelain retaining market share and improving competitiveness.

|

|