3.4.1.2 Steatite

Steatite is a ceramic material based on

natural raw materials and consists mainly of soapstone (Mg(Si4O10)(OH)2),

a natural magnesium silicate, with the addition of clay and

feldspar or barium carbonate. Steatite is usually sintered

to a high density.

The type of flux used influences the electrical properties

of this material, leading to a distinction between normal

steatite and special steatite, also known as high-frequency

steatite.

Special steatite is defined in international standards as

steatite with a low loss factor, and is not only used in low-loss

high-frequency parts, but because of its excellent workability

it is also used for the manufacture of components with thin,

constant thickness. This allows thermally induced mechanical

stresses to be controlled.

This material also permits the economical manufacture of products

with very small tolerances due to its low shrinkage during

sintering. It is also less abrasive to tools than any other

ceramic, making it particularly suited to dry pressing.

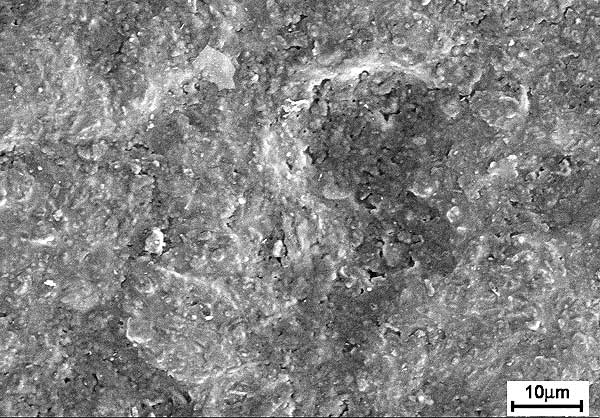

Figure 4: Steatite (C 221) surface with firing

skin

Special steatite possesses excellent mechanical

and dielectric properties, and has been used for more than

90 years in various applications in electrical engineering,

for electronic parts and in heat engineering. Typical applications

include sockets, control housings, insulating beads, low-voltage

power fuses and base plates.

For special applications such as heating cartridges, porous

steatite is often used, since it can be easily machined even

after sintering, and has a very good thermal shock resistance.

|

|