4.2 Finishing

4.2.1 Hard machining

Final machining (hard machining)

is carried out on fully sintered items that have been brought

as close as possible to the final dimensions through forming,

or through green or white machining. The closest possible

tolerances can be achieved through a final machining procedure

involving material removal.

Tight requirements for dimensional precision and the wide

variety of geometries and surface qualities require the use

of modern machine tools for processing ceramic components.

Due to the high hardness of ceramic materials, diamond tools

(bonded or pastes) are used here almost exclusively.

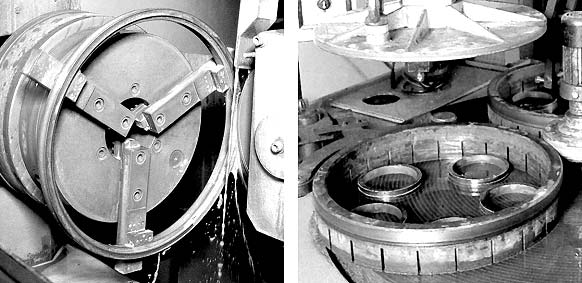

Figures 65 and 66: Hard machining components:

grinding and lapping

Table 7: Possible finishing processes.

Grinding is of central

importance. A large number of factors affect the grinding

process and the result of the grinding. For this reason, the

appropriate grinding wheel for any particular workpiece is

selected with great care for its grain type and size, the

bonding, and the hardness of the wheel. Extremely flat surfaces

such as for slip rings and sealing surfaces must be lapped

and then polished after grinding.

|