4.1.6 Machining

As shown in figure 62, green machining

(after drying), white machining (after burning

out and prefiring) and hard machining (after

sintering) are to be distinguished.

Figure 62: Classification of green, white

and hard machining in the production process

Green machining

is performed on the dry parts while they still contain organic

additives. It is well suited to the manufacture of individual

parts and small series. It is also used with large series

to manufacture shapes that cannot be realised directly by

initial forming procedure, such as holes transverse to the

direction of dry pressing.

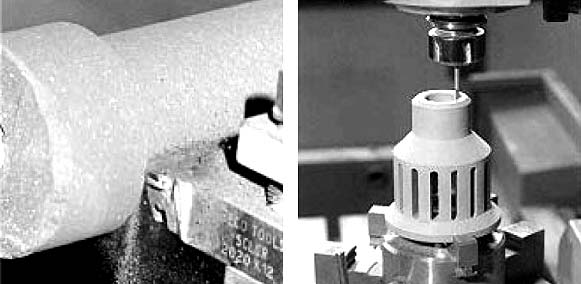

Figures 63 and 64: Components being machined

green

White machining

is performed on the prefired parts, now free from organic

additives. The strength depends on the prefiring.

In this way, extremely high removal rates be achieved with

relatively low tool wear using conventional, ceramic or diamond

coated tools. This process is used by manufacturers both for

making prototypes and for mass production.

|