3.4.2.8 Lead

zirconate titanate

Currently the most important piezoelectric

ceramic materials are based on mixed oxide crystal

system consisting of lead zirconate and lead titanate known

as lead zirconate titanate (PZT).

The specific properties of these ceramics,

such as the high dielectric constant, are dependent on the

molar ratio of lead zirconate to lead titanate as well as

on substitution and doping with additional elements. A wide

range of modifications can be implemented in this way, creating

materials with highly varied specifications.

The piezoelectric effect

The piezoelectric effect links both electrical

and mechanical properties.

Piezoelectricity refers to a linear electro-mechanical

interplay between the mechanical and electrical states of

a crystal.

The direct piezoelectric effect

refers to an electrical charge, detectable as a voltage, being

created in proportion to mechanical deformation of the crystal.

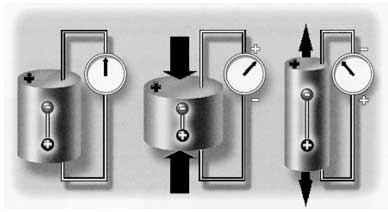

| Figure 21: |

Piezoelectric effect resulting from an external

force. The polarity of the electric charge depends on

the direction of the applied force. |

The reciprocal or inverse piezoelectric

effect refers to a deformation that arises in proportion to

an external electrical field created by the application of

an electrical voltage.

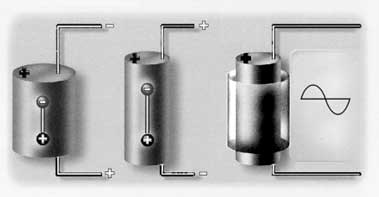

| Figure 22: |

he inverse piezoelectric effect under the

influence of external electric fields. The dimensions

of the body vary with the change in voltage. |

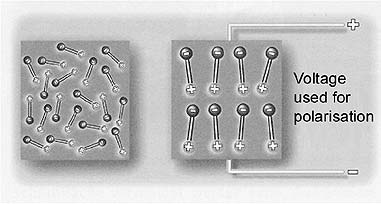

Principles

The piezoelectricity of ferroelectric materials is a consequence

of the existence of polar areas (domains) whose orientation

changes as result of the polarisation, i.e. of the application

of an electrical voltage. The polarisation is associated with

a change in length,  S. S.

Figure 23: Electric dipoles in a piezoelectric

material before and after polarisation.

Lead zirconium titanate Pb(Zrx Ti(1-x)) O3

is processed in polycrystalline form. The two most common

shaping methods are pressing and the tape casting process.

The green body acquires its ceramic properties through firing.

The piezoceramic, however, only acquires its technically interesting

piezoelectric properties through a polarisation process.

| Figure 24: |

Diagram of the domains in lead

zirconate titanate before, during and after polarisation

S

= change in length during polarisation S

= change in length during polarisation

Sr

= residual changing length after the polarisation process Sr

= residual changing length after the polarisation process |

Resonance modes in piezoelectric componen

All the components applied as sensors and actuators exploit

the fundamental vibration modes.

Figure 25: Fundamental vibration modes in

piezoceramic components

Structural forms

If the piezo-ceramic consists of one layer,

we speak of single layer technology. If the piezo-ceramic

component consists of a number of active piezo-ceramic layers,

we speak of multi-layer technology. Nowadays it is usual for

piezo-ceramic plates, strips, rings, domes, small tubes and

a large number of special geometries to be manufactured.

Their compact form means that piezo-ceramic

transducers take up little space, and use little energy when

used as actuators. Multi-layer actuators

are used when large movements are required that can also create

high forces.

The individual layers are connected electrically in parallel

so that the external voltage remains small.

Figure 26: Configuration and sectional diagram

of a monolithic multi-layer piezo-ceramic actuator.

Another variant is represented by the bending transducer.

This is created if, for instance, piezo-ceramic elements are

glued to a carrier material. The piezo-ceramic material reacts

with a change in its length when electrically stimulated.

The result, similar to that of a bimetal strip, is a large

change in the shape of the composite material, depending on

the voltage and its polarity, associated with moderate forces.

Figure 27: Application of the operating voltage

causes the piezo-ceramic to contract, causing the pair to

bend

Actuators with a passive layer and a piezo-ceramic component

are called monomorphic. A bimorphic bending transducer consists

of two piezo-ceramic elements without an intermediate passive

layer. A system consisting of two piezo-ceramic components

together with a passive intermediate layer is referred to

as trimorphic. A multimorphic bending transducer consists

of a large number of piezo-ceramic components, and does not

have passive intermediate layers.

Figure 28: Structural variants of piezo-ceramic

bending converters with

P = polarisation direction and E = direction of the electrical

field

Depending on the individual design of the bending transducer,

movements of several millimetres, forces of up to a few newtons,

and remarkably short movement times can be achieved. The bending

transducer can therefore be used as a powerful and rapidly

operating actuator.

Piezo-ceramics have won many applications

in electronics, in the motor vehicle industry, in medical

technology, in equipment and machine construction and consumer

applications:

piezo-ceramic components are used as transducers in telecommunications,

acoustics, hydro-acoustics, materials testing, ultrasonic

processing, liquid atomisation, flow measurement, level measurement,

distance measurement and medical technology. They are applied

as actuators in micro-pumps, in optical systems, gas valves,

low-pressure engineering, in inkjet printers, textile machines

and in Braille modules (reading devices for the blind). Applied

as sensors they react to force, pressure and acceleration,

making it possible to monitor a wide range of processes.

|