4.2.2.1 Ground

Surfaces

The characteristic of grinding is the overlapping

of a large number of scraping movements on fixed paths taken

by grinding grains in one particular direction parallel to

the surface of the workpiece. The scraping movement of the

cutting grains directly induces micro-cracks, brittle breakage

and/or plastic flow, and hence the ductile separation of ceramic

particles.

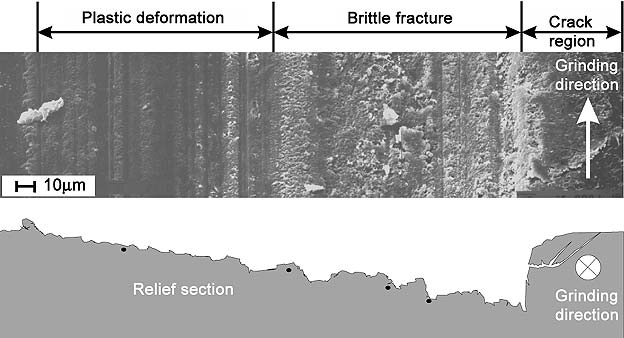

Figure 67 shows machining tracks which illustrate

the mechanisms by which material becomes separated, with areas

of primarily plastic deformation, of primarily brittle fracture

and of a crack may clearly be distinguished. The crack area

is characterised by microscopic axial, radial and lateral

cracks.

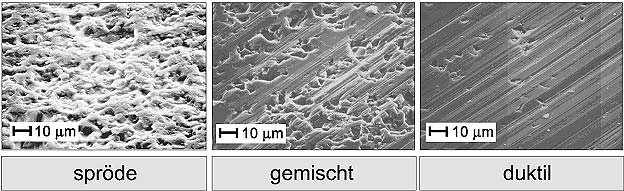

Surfaces whose creation has primarily been

influenced by plastic deformation procedures typically display

scoring, rounding, stratification, flaking and a relatively

small number of break-outs. The process is called "ductile

cutting".

In contrast to this, break-outs, pile-ups, facetting and spalling

are typical of "brittle cutting".

Grinding a surface usually results both in ductile and in

brittle cutting. The dominant mechanism of material separation

depends on the local stress conditions on the individual grains

of the ceramic microstructure during the scraping process.

The changeover from brittle to ductile cutting depends in

particular on exceeding a critical cutting thickness at the

individual grain, but also on the micro-geometries of the

cutting grains.

Bild 67: Unterschiedliche Werkstofftrennmechanismen

bei geschliffenem Siliciumnitrid

Figure 68: Ceramic surfaces subjected to

brittle, mixed and ductile grinding

|