4.2.2.2 Honed

surfaces

The overlaying of a large number of fixed-force

scraping movements of cutting grains over the material, involving

wide-area tool contact and a primary active direction parallel

to the surface of the workpiece are characteristic of honing.

The cutting speed involved in honing is perhaps an order of

magnitude lower than that used for grinding, which means that

thermal effects are comparatively small. As a result of this,

honed ceramics surfaces generally do not display any signs

of fusion or thermally induced cracks. As with grinding, both

ductile and brittle material separation mechanisms occur next

to one another. The penetration depth of the cutting grains

and the cutting speed are the primary factors influencing

which of these mechanisms will be dominant.

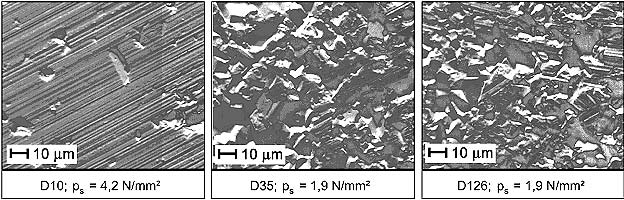

Figure 69: Surface generation depending on

the cutting grain size, D, and

the contact pressure, ps, when honing aluminium oxide

Higher cutting speeds have a positive effect

on the rate at which material is removed when honing with

brittle cutting. Higher cutting speeds are, however, are a

disadvantage for the surface quality due to the increased

tendency to induce cracks that lead to break-outs and spalling.

|

|